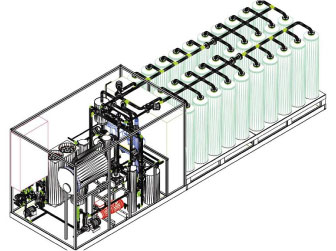

Cutting-edge Solutions from a Transformer Oil Regeneration Plant

Cost-Effective and Eco-Friendly Transformer Upkeep With Regenerated Oil

The integration of regenerated oil in transformer upkeep provides a compelling strategy for companies seeking to enhance both cost-efficiency and eco-friendliness. By using oil that preserves performance requirements similar to virgin options, companies can significantly reduce functional prices while concurrently minimizing their environmental impact. This technique not just addresses the monetary problems associated with waste disposal and constant oil adjustments however additionally adds to more comprehensive sustainability initiatives. However, the effects of this shift extend past instant advantages; recognizing the complete scope of its benefits requires a better evaluation of the principles and techniques involved.

Recognizing Regenerated Oil

Restored oil, frequently described as re-refined oil, is a critical part in the upkeep of transformers, giving both ecological and financial advantages. This oil is stemmed from used mineral oils that have actually undergone an extensive filtration procedure, effectively removing pollutants and recovering the oil to a quality comparable to virgin oil. The regrowth procedure commonly includes several stages, including physical splitting up, chemical treatment, and purification, guaranteeing that contaminations such as sludge, water, and heavy metals are eliminated.

The utilization of regenerated oil in transformers is vital for enhancing efficiency and prolonging tools life-span. Premium re-refined oil keeps its dielectric residential properties, guaranteeing efficient insulation and protecting against electrical malfunctions. In addition, it possesses superb thermal conductivity, which assists in handling the operational temperature levels of transformers, ultimately boosting their dependability and efficiency.

In addition, adopting regrowed oil not only sustains cost-effective maintenance techniques however also decreases the need for brand-new oil production, therefore conserving natural deposits. Transitioning to re-refined oil is a smart choice for organizations intending to keep high operational criteria while concurrently taking care of budget plan constraints. Recognizing the residential or commercial properties and advantages of restored oil is essential for informed decision-making in transformer maintenance methods.

Environmental Benefits

Using regrowed oil in transformer upkeep supplies significant environmental advantages that add to lasting practices within the energy market. One of the primary advantages is the decrease of waste oil disposal, as regenerated oil is derived from the recycling of made use of transformer oil, considerably lowering the quantity of contaminated materials produced. This procedure aids alleviate the environmental risks associated with improper disposal techniques, which can result in dirt and water contamination.

In addition, the regrowth procedure preserves natural deposits by reducing the need for new base oil production - Transformer Oil Regeneration Process. This conservation initiative not just lowers the removal influence on environments yet likewise lowers the carbon footprint connected with oil manufacturing. By embracing regrowed oil, companies can advance their commitment to ecological stewardship and line up with global sustainability objectives

Moreover, using regenerated oil boosts the total efficiency of transformers, causing lowered energy losses and lower greenhouse gas exhausts. As the energy sector progressively encounters pressure to diminish its ecological effect, welcoming restored oil stands for an aggressive strategy to accomplishing both operational and ecological purposes. In recap, the environmental advantages of using regenerated oil are multifaceted, advertising a healthier earth while supporting the power market's shift in the direction of sustainability.

Expense Savings and Efficiency

Using regenerated oil in transformer maintenance can lead to significant price financial savings and boosted functional efficiency for energy companies. Restored oil, generated with advanced purification processes, offers equivalent efficiency to new oil at a fraction of the cost. By reusing oil that would otherwise be disposed of, business can lower their purchasing expenditures while minimizing garbage disposal costs.

Furthermore, the long term life process of regenerated oil translates to minimized frequency of oil changes, causing lower labor expenses and lowered downtime for try these out maintenance tasks. Reclaimed Transformer Oil. This not only improves functional effectiveness but also permits an extra streamlined upkeep routine, allowing firms to allocate sources much more successfully

Additionally, the usage of restored oil can result in lower insurance costs as a result of its eco-friendly account. As energy firms deal with raising scrutiny regarding their ecological effect, taking on lasting methods such as utilizing restored oil can strengthen their credibility and possibly draw in investment.

Inevitably, the combination of regenerated oil into transformer upkeep techniques provides a critical chance for power firms to accomplish substantial price financial savings while advertising functional performance, thereby lining up monetary performance with environmental obligation.

Comparison With Standard Oils

While conventional oils have long been the requirement in transformer upkeep, a thorough contrast reveals that regenerated oils offer several benefits that enhance efficiency and sustainability. Standard mineral oils, while reliable, usually present ecological threats, such as contamination and disposal problems. In contrast, regenerated oils are stemmed from recycled products, substantially minimizing their ecological footprint.

They normally show exceptional oxidative stability, which converts to longer solution life and lowered regularity of oil changes. This particular not only improves transformer performance yet additionally lessens downtime and upkeep costs.

Moreover, regenerated oils provide superb dielectric properties, making sure efficient electric insulation. This top quality is important in keeping transformer performance under varying functional problems. Using regenerated oils likewise straightens with global sustainability objectives, appealing to companies devoted to decreasing their carbon impact. In general, the advantages of regenerated oils over standard oils highlight their potential to reinvent transformer upkeep techniques, using a much more reliable and responsible option.

Implementation in Upkeep Practices

As soon as the assessment is full, a customized strategy for transitioning to regenerated oil needs to be created, taking into consideration variables such as compatibility with existing products and operational conditions. Educating for upkeep personnel is essential, as they must recognize the unique residential or commercial properties of regenerated oils and exactly how to handle their YOURURL.com application efficiently.

Applying a strenuous tracking program will promote the assessment of efficiency metrics post-implementation, ensuring the regenerated oil meets the required functional criteria. Transformer Oil Regeneration Plant. Furthermore, establishing a regular maintenance schedule will certainly assist in determining potential issues early and allow for timely corrective activities

Conclusion

In verdict, the adoption of regrowed oil for transformer maintenance presents a feasible service that straightens economic benefits with environmental sustainability. By decreasing prices connected with oil changes and waste disposal, while simultaneously expanding the lifespan of tools, organizations can boost operational efficiency. The change to restored oil not just reduces ecological impacts however also sustains more comprehensive sustainability purposes, making it a sensible choice for modern-day maintenance practices in the power field.

Regrowed oil, usually referred to as re-refined oil, is an essential part in the upkeep of transformers, giving both ecological and economic advantages. This oil is acquired from used mineral oils that have undergone a Regenerated Transformer Oil detailed purification process, properly eliminating impurities and recovering the oil to a high quality similar to virgin oil.Moreover, adopting regenerated oil not just sustains economical upkeep strategies but also lowers the requirement for brand-new oil manufacturing, thereby saving natural sources. One of the main advantages is the reduction of waste oil disposal, as regenerated oil is derived from the recycling of utilized transformer oil, substantially decreasing the volume of hazardous waste created. Regrowed oil, produced via sophisticated filtration processes, provides equivalent performance to new oil at a fraction of the cost.